HOTSPOTS

Select a

touchpoints

and find out!

the secret to its success

The first Lely Vector automatic feeding system was installed on a test farm a decade ago. Today there are more than 1,000 mixing and feeding robots in operation. The Vector system is successfully used in a variety of dairy and beef cattle farms in 31 countries. And the secret to its success? Continuous innovation and further development, based on expertise and excellence. By building on test farms’ practical experiences, conducting field research and simply trying out new things, we’ve improved the Vector system. Here’s an outline of the key improvements made to help farmers remain profitable, sustainable, and future-proof.

1

2

3

4

HOTSPOTS

the secret to its success

The first Lely Vector automatic feeding system was installed on a test farm a decade ago. Today there are more than 1,000 mixing and feeding robots in operation. The Vector system is successfully used in a variety of dairy and beef cattle farms in 31 countries. And the secret to its success? Continuous innovation and further development, based on expertise and excellence. By building on test farms’ practical experiences, conducting field research and simply trying out new things, we’ve improved the Vector system. Here’s an outline of the key improvements made to help farmers remain profitable, sustainable, and future-proof.

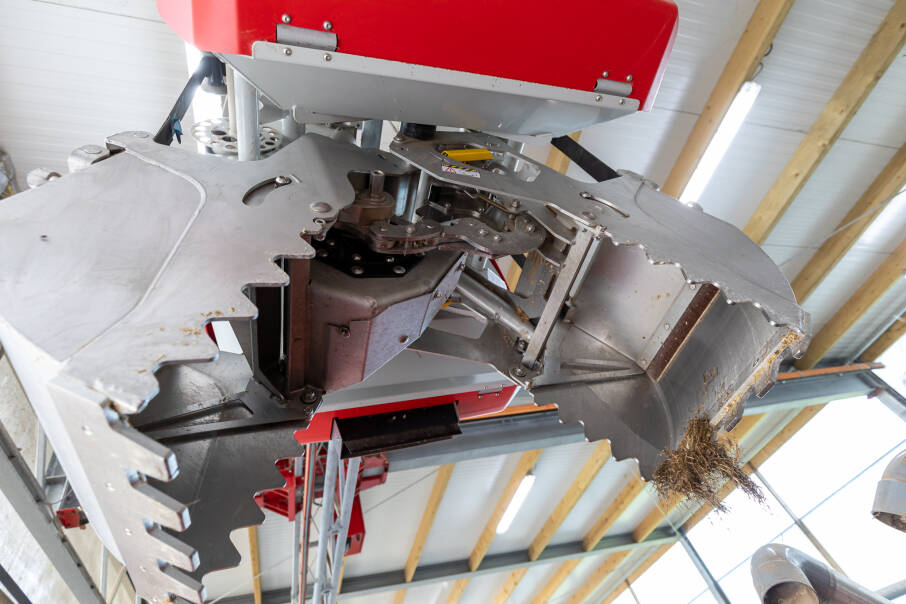

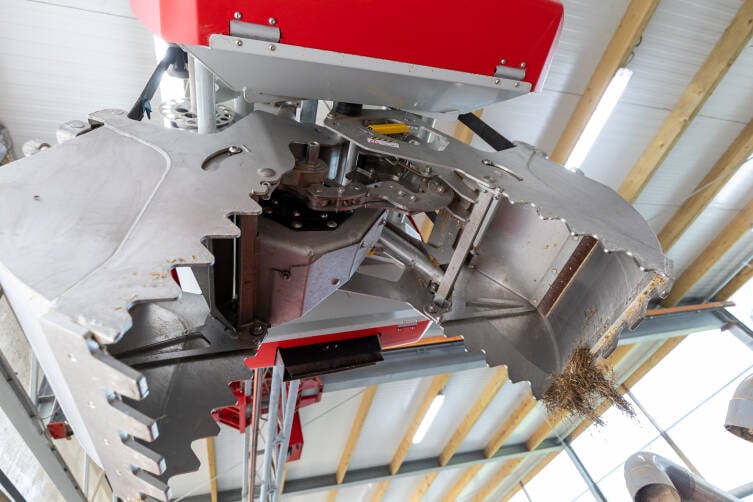

1. Feed grabber

A laser scans the highest point of a silage block or bale and grabs the feed from there. This ensures the silage clamp is emptied evenly. Hydraulics have been replaced with an electric motor – making operation faster and quieter. The bucket is also made of stainless steel, to extend its lifetime, and its new shape means it offers better closure.

1

2

3

4

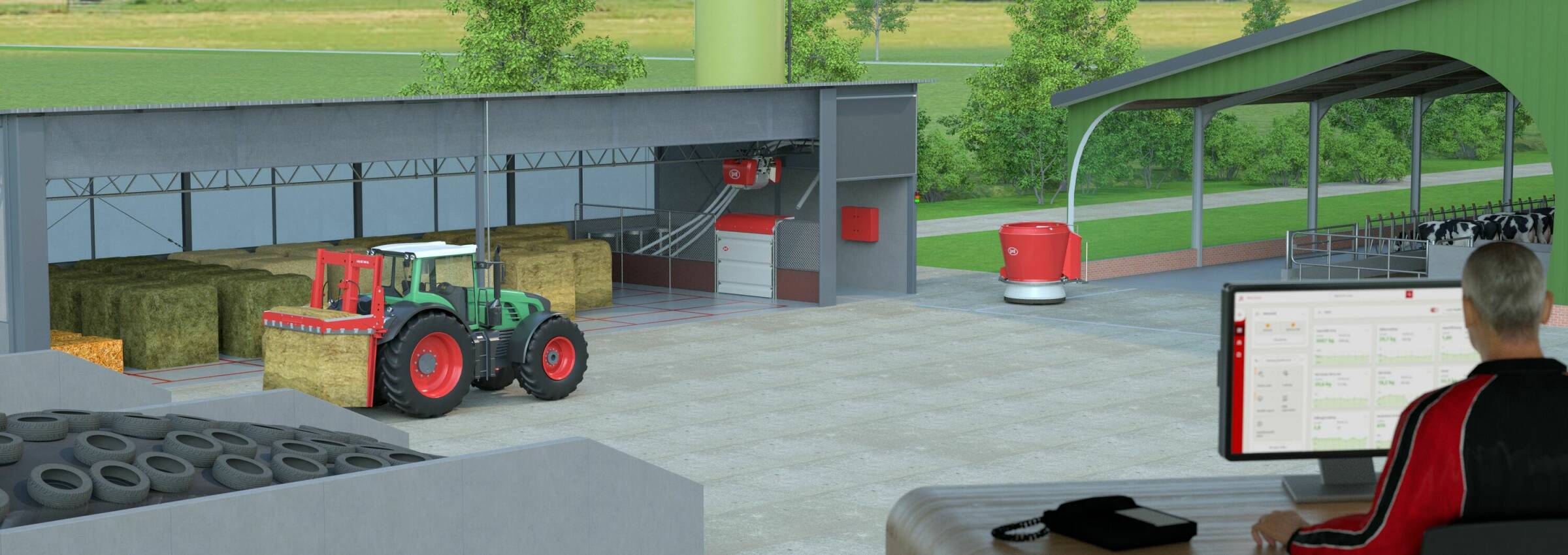

A new version of the mixing and feeding robot, the MFR M2, was introduced in 2018. Key parts are now made with more sustainable materials, which also give them a longer life expectancy. The design also makes maintenance easier, with the drive and electrical components being much more accessible. In 2020, obstacle detection sensors were added to improve safety.

Technology to produce reports, which give an overview of the ration fed and costs for individual animals or a group in a specific time frame, was added in 2015. Dairy farmers can, for example, easily check their feed costs per 100kg of milk and, therefore, their feed efficiency. Since 2016, the management software has offered customers more insights and control over their feeding process and their results, to help increase the return on their feeding investment. Lely redesigned the entire software system, based on user experience. And we are now integrating the Vector management system into the new Lely Horizon farm management platform.

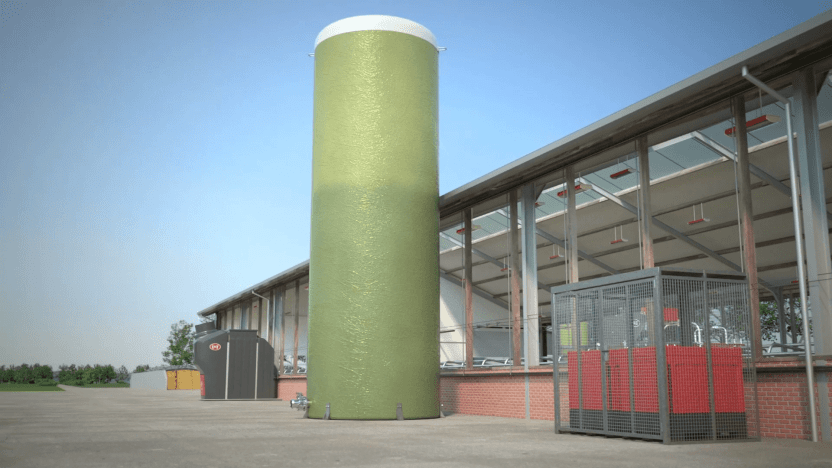

In 2017, Lely added the BC 180 XL silage cutter to its feeding technology portfolio, which offers high cutting capacity and is designed for even the toughest silage. Offering an extra 105cm of depth, the Lely BC 180 XL is ideal for filling feed kitchens. After jointly introducing the first modular feed kitchen with ID Agro in 2017, Lely began an official partnership in 2021. Further development has resulted in a faster implementation time and short communication lines during the planning and installation of the Vector system.