with love

ZAO ‘Sovkhoz imeni Lenina’ has always strived to be Russia’s top herd, so innovation has been key. In 2015 the dairy switched to robotic milking and that’s where Lely stepped in. Farm manager Danila Kozlov and service engineer Yuri Zhiltsov share their experiences.

HAPPY FARMER

- Farm founded: 1918

- Owner: ZAO ‘Sovkhoz imeni Lenina’

- Location: Moscow, Russian (closest farm to the Kremlin)

- Herd size: 500 cows

- Type and number of Lely robots: Eight A4 Astronauts

- Support: Lely Center ‘Yasnogor Farms’

Farm facts

Danila, why did you switch to automation?

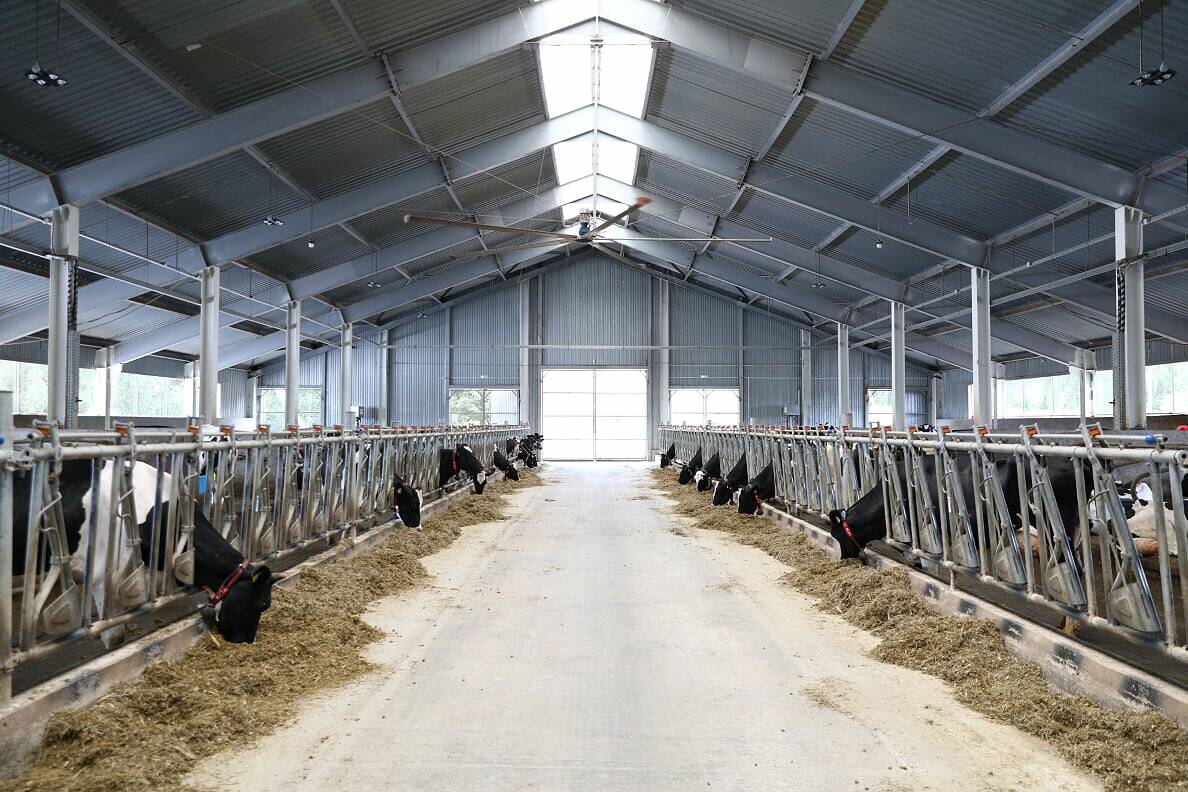

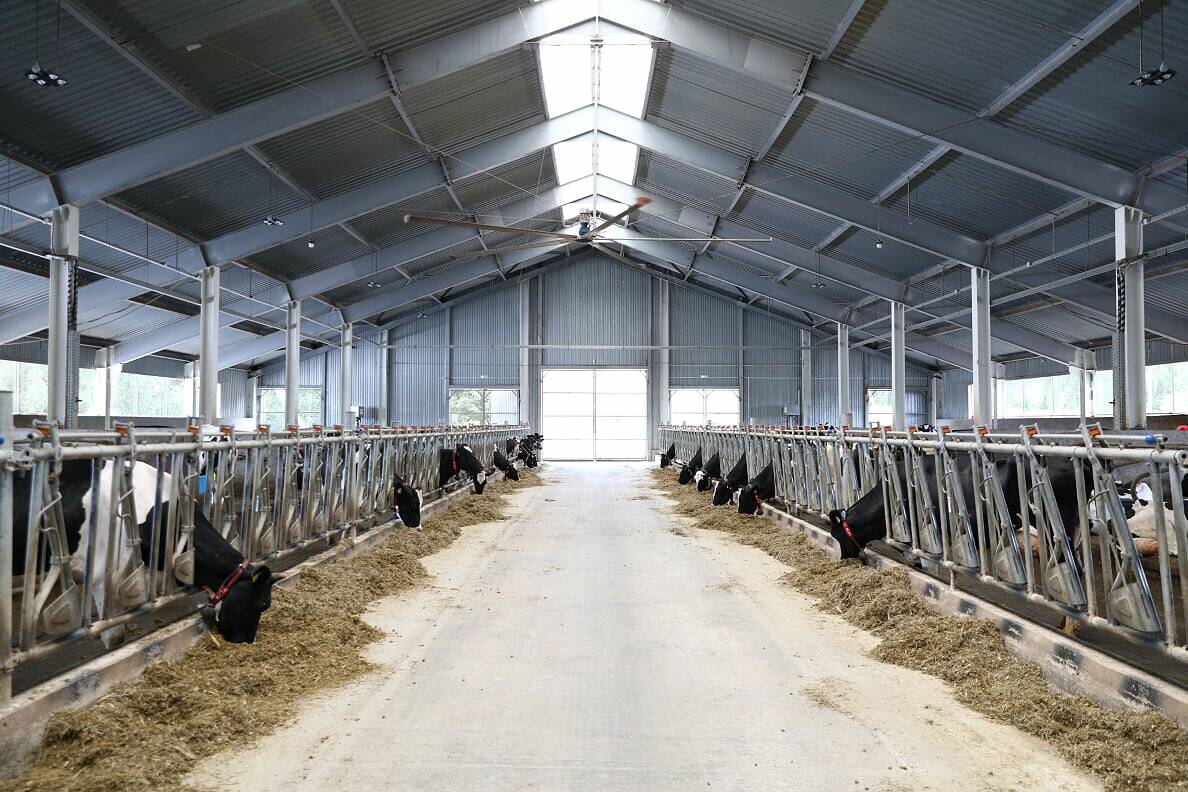

'In our drive to become the best, moving to Lely robots was the next logical step. Prior to installation, our 230-cow herd was housed in a tie-stall barn and everything was done by hand. We added a further 200 cows to the herd, which were housed in a new free-stall barn. We employed six staff to milk the herd, as well as a driver to transport them to the farm three times a day. There was a lot of old equipment and our mechanic regularly worked 14-hour days.'

What has changed since

Lely installed the robots?

'We never imagined that things would change as much as they have. Our cows are now averaging 36 litres of milk per day, with no need for milking staff and all within an eight-hour working day. That’s a huge change for the better for our team. Their work-life balance has significantly improved. And the cows also have better lives – they choose when they want to be milked, and eat, drink or rest. They have freedom.'

Describe your relationship with Lely?

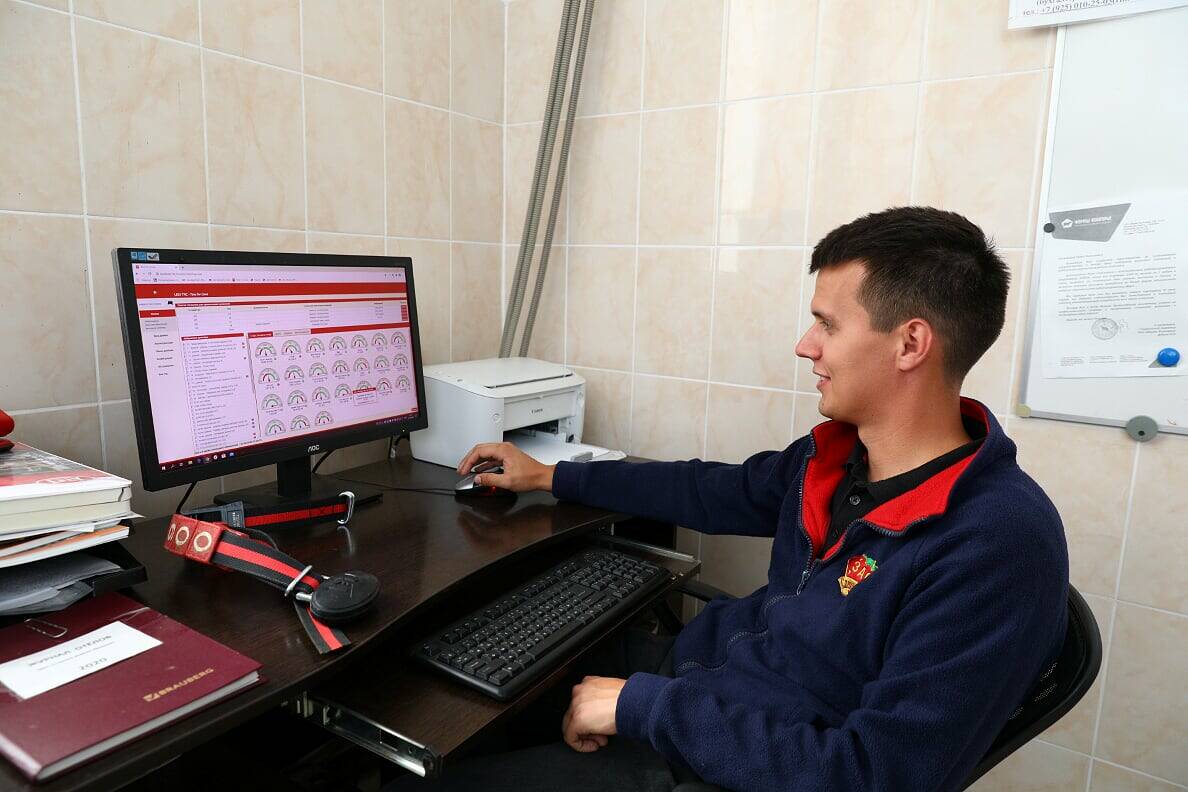

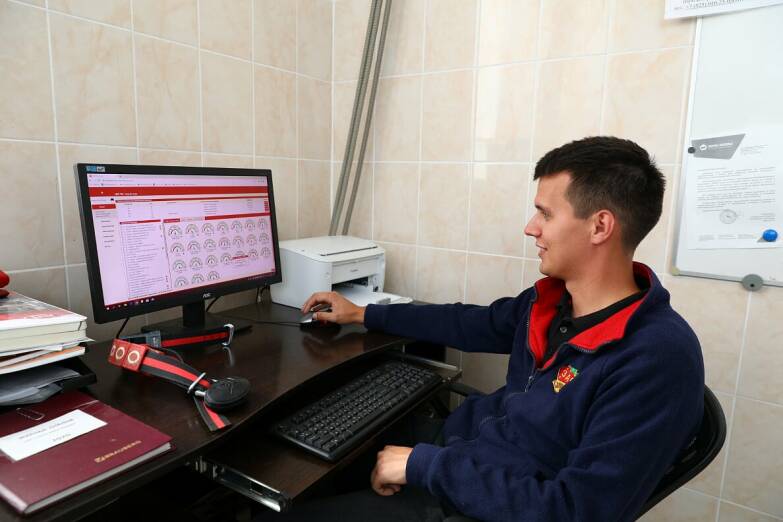

'With Lely, we can move our herd and dairy business further forward. We can identify areas to improve, such as milk production, as well as any issues with the herd and dairy equipment. Lely’s 24/7 hotline to a dealer is really helpful. We can ask any question, or ask for help in order to understand the operation of the equipment, reports in T4C, and so on. This contact and support produces as much milk as the equipment itself, because managing the herd competently is vital.

When we made the transition to robotic milking, the Lely Center helped us to retain our ‘problem’ cows. Just two out of 430 cows ‘couldn’t make friends’ with the robots. This is an amazing result when you consider that we didn’t make any advanced preparations for the system change.'

Yuri, what were this customer’s

starting points and challenges?

'It was important, back in 2015, to build a unit that met all the latest requirements. We had continuous negotiations with the client to ensure that the farm would be ‘future-proof’. It was the first Dairy XL project for us. We developed a plan for the phased launch of each robot, so the staff were easily able to adjust to the operation with the new equipment. The first four-robot barn was up and running by April 2016.

TSS and FMS provided comprehensive training for staff working with the Astronauts and T4C. The farm manager was trained to work with reports. A year later, the second barn began operating.

The service department also ensures the quality of the milk. In 2019, the farm had the top performing Lely robots in Russia, with a record milk yield of 42 litres per cow per day. This, with 24/7 support, means the client is happy and is able to move forward.'

HAPPY FARMER

with love

ZAO ‘Sovkhoz imeni Lenina’ has always strived to be Russia’s top herd, so innovation has been key. In 2015 the dairy switched to robotic milking and that’s where Lely stepped in. Farm manager Danila Kozlov and service engineer Yuri Zhiltsov share their experiences.

- Farm founded: 1918

- Owner: ZAO ‘Sovkhoz imeni Lenina’

- Location: Moscow, Russian (closest farm to the Kremlin)

- Herd size: 500 cows

- Type and number of Lely robots: Eight A4 Astronauts

- Support: Lely Center ‘Yasnogor Farms’

Farm facts

Danila, why did you switch to automation?

'In our drive to become the best, moving to Lely robots was the next logical step. Prior to installation, our 230-cow herd was housed in a tie-stall barn and everything was done by hand. We added a further 200 cows to the herd, which were housed in a new free-stall barn. We employed six staff to milk the herd, as well as a driver to transport them to the farm three times a day. There was a lot of old equipment and our mechanic regularly worked 14-hour days.'

What has changed since

Lely installed the robots?

'We never imagined that things would change as much as they have. Our cows are now averaging 36 litres of milk per day, with no need for milking staff and all within an eight-hour working day. That’s a huge change for the better for our team. Their work-life balance has significantly improved. And the cows also have better lives – they choose when they want to be milked, and eat, drink or rest. They have freedom.'

Yuri, what were this customer’s

starting points and challenges?

'It was important, back in 2015, to build a unit that met all the latest requirements. We had continuous negotiations with the client to ensure that the farm would be ‘future-proof’. It was the first Dairy XL project for us. We developed a plan for the phased launch of each robot, so the staff were easily able to adjust to the operation with the new equipment. The first four-robot barn was up and running by April 2016.

TSS and FMS provided comprehensive training for staff working with the Astronauts and T4C. The farm manager was trained to work with reports. A year later, the second barn began operating.

The service department also ensures the quality of the milk. In 2019, the farm had the top performing Lely robots in Russia, with a record milk yield of 42 litres per cow per day. This, with 24/7 support, means the client is happy and is able to move forward.'

Describe your relationship with Lely?

'With Lely, we can move our herd and dairy business further forward. We can identify areas to improve, such as milk production, as well as any issues with the herd and dairy equipment. Lely’s 24/7 hotline to a dealer is really helpful. We can ask any question, or ask for help in order to understand the operation of the equipment, reports in T4C, and so on. This contact and support produces as much milk as the equipment itself, because managing the herd competently is vital.

When we made the transition to robotic milking, the Lely Center helped us to retain our ‘problem’ cows. Just two out of 430 cows ‘couldn’t make friends’ with the robots. This is an amazing result when you consider that we didn’t make any advanced preparations for the system change.'