learning culture

Lean is a globally recognised concept that is believed to go back to the Bell Telephone company nearly 90 years ago. Working according to the Lean methodology is a team effort and therefore applicable to everyone.

As Lely we are globally committed to promoting and supporting a Lean culture, allowing us to reduce complexity and streamline processes while reducing or even eliminating waste. This methodology allows us to continually focus on what is best for our customers: the farmers and their dairy cows! Let’s take a look at how the Lely factory in Pella implements the Lean principles in their daily work processes.

+

+

+

+

+

HOTSPOTS

5

4

5

3

2

4

3

2

1

Eight waste streams

Within Lely, we identify and acknowledge 8 types of waste. By being aware of all waste streams, we strive for reducing waiting times, minimize unnecessary movements (transportation), prevent the production of more products than needed and identify excess materials and products that are not being processed.

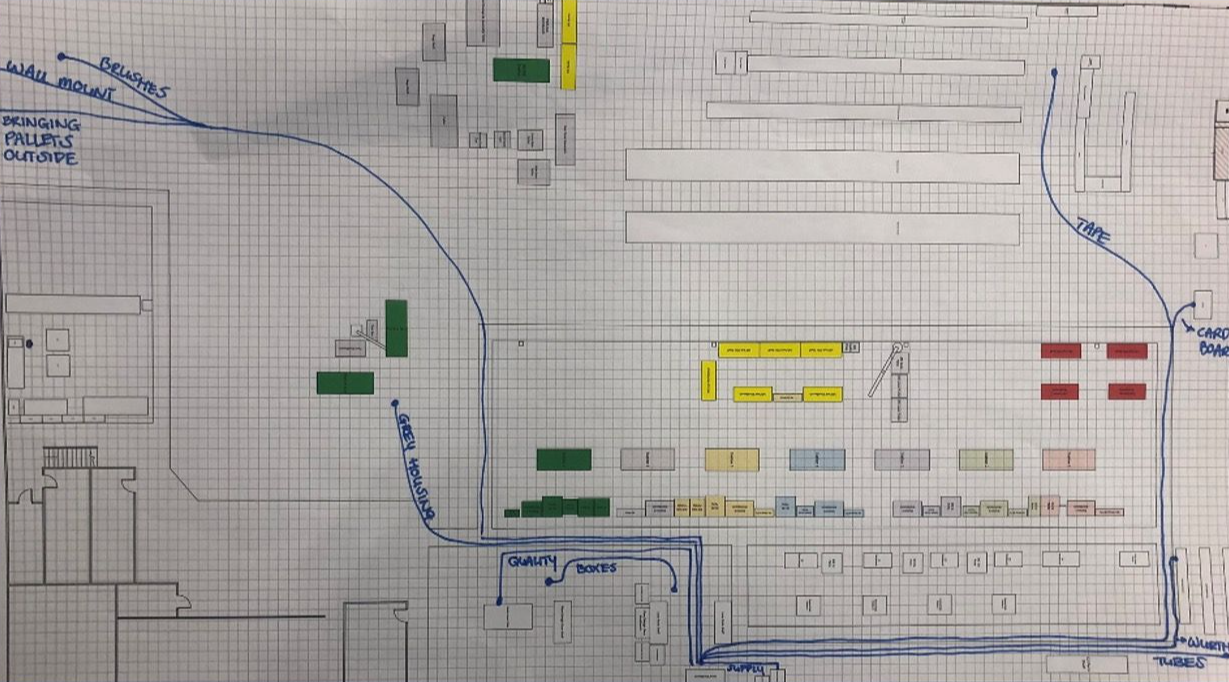

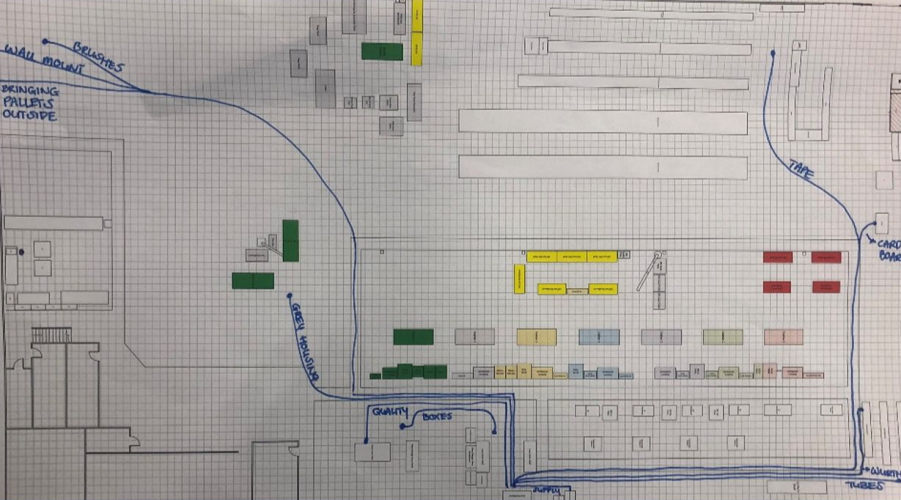

Spaghetti Charts

Spaghetti charts support us in identifying waste and provide guidance on allocating further opportunities to streamline our daily work processes. The steps for creating an efficient spaghetti chart include observing and mapping out current workflows, followed by intensive analysation which enable the allocation of possible bottlenecks.

5S – Workplace optimisation

5S implements safe, ergonomic and efficient work areas and is often considered as the foundation for a continuous improvement-based work culture. 5S – for instance – underlines the importance of sorting so items that are no longer required can be removed, allowing focus to shift to the identification of missing items. Standardizing is also part of the 5S principles. Establishing standards will reduce training and searching time and enable an easy allocation of missing items or information.

Kan Ban – Demand Pull System

At the Lely factory in Pella, the ‘Kan Ban’ demand pull system simplifies the picking process for parts required at the assembly line. According to the ‘what you need when you need it’, Kan Ban contributes to better material visibility, productivity optimisation and reducing waste materials.

Continuous Improvement

Lely’s Continuous Improvement Competence Center (CICC) provides guidance and the necessary tools to help Lely employees reach their improvement-related goals. The CICC policy – aimed on making our jobs easier and above all more fun - is based on the Lean Six Sigma philosophy.

1

Lean is a globally recognised concept that is believed to go back to the Bell Telephone company nearly 90 years ago. Working according to the Lean methodology is a team effort and therefore applicable to everyone.

As Lely we are globally committed to promoting and supporting a Lean culture, allowing us to reduce complexity and streamline processes while reducing or even eliminating waste. This methodology allows us to continually focus on what is best for our customers: the farmers and their dairy cows! Let’s take a look at how the Lely factory in Pella implements the Lean principles in their daily work processes.

is a learning culture

HOTSPOTS